Everything you need to know about continuous surface mining

What is continuous surface mining?

Continuous surface mining is a method of mineral extraction that uses specialized equipment instead of explosives. Surface miners cut through the ground in a methodical, row-by-row and layer-by-layer manner, which results in a more controlled and efficient mining process. This approach has numerous advantages, including the ability to produce uniform particle sizes, safety and mine access considerations, potentially eliminating the need for a primary crusher, and minimizing waste and contamination.

In this video, Vermeer mining experts Mike Selover and Gregg Van Roekel take you behind the scenes of this increasingly popular method and show you the types of surface mining equipment that make it possible.

How continuous surface mining works

Using a surface miner allows you to methodically mine or prep a site — optimizing productivity and precision while eliminating many of the safety challenges and restrictions associated with drilling and blasting.

The surface miner cuts row by row and layer by layer while producing consistent particle sizes that do not typically require additional screening or crushing.

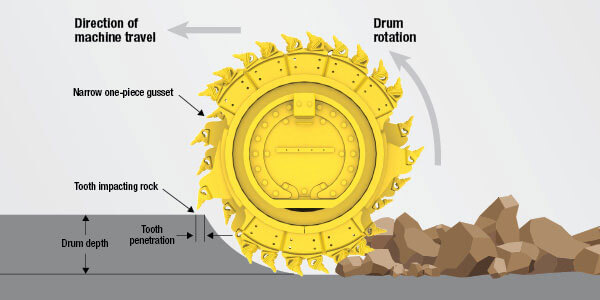

A top-down cutting technique allows teeth to gain maximum penetration, helping minimize fines and produce consistently sized material that is ready to be hauled away.

The advantages of surface miners versus drill and blast

Surface miners

- Produce a smaller, more consistent particle size.

- Help eliminate the primary crusher step.

- Help reduce fines to increase usable product.

- Increase payload in mine trucks over drill and blast material.

- Access areas of surface mines where drilling and blasting cannot be done because of physical or permit limitations.

- Produce a smooth floor to help minimize wear and tear on mine trucks and loaders.

- Help operations work next to power lines, pipelines, urban areas and other existing structures.

- Mine reserves that otherwise may be left behind.

- Help get the mine or quarry to market faster.

Drill and blast

- Produce larger, inconsistent particle sizes.

- Requires the use of a primary crusher.

- Results in fines and unusable product.

- Lower payloads in mine trucks.

- Restricted use in many areas limits material access.

- Creates volatile mine floors and conditions.

- Cannot be performed near power lines, pipelines, urban areas and other existing structures.

- Often results in mine reserves being untouched or left behind.

- Can be slower to get the mine or quarry to market.

Explore more about continuous surface mining.

Learn more about the many advantages of surface mining and the many applications and uses of this specialized mining equipment.