Horizontal and tub grinder tooling

We have what you need

Turning waste into a useful byproduct requires innovative solutions and machinery like Vermeer horizontal grinders and tub grinders. These machines endure some of the toughest jobsite conditions. It’s essential on the jobsite to have quality replacement wear parts for your grinder at all times — that’s why Vermeer offers several different replacement options for popular machines. Whether it is grinder tips, screens or drums, we have what you need.

Grinder screens

Vermeer boasts an exclusive in-house grinder screen manufacturing process to help maximize the performance of customers' horizontal and tub grinders. Screen styles are available in a variety of sizes making it convenient to find the right fit for optimum productivity and product consistency.

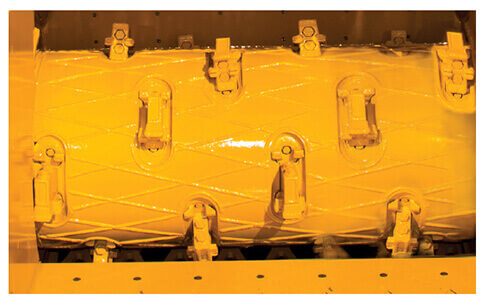

Series III duplex drums

Our patented Series III duplex drum design features reversible hammers and cutter tips for ease of maintenance and can extend wear life. The Series III is built off the proven cutting performance of previous Vermeer duplex drum designs and makes maintenance more convenient.

Grinder tips

With high carbide coverage and several different styles, Vermeer grinders are built to last while tackling tough jobsites. Paired with a Vermeer horizontal grinder or tub grinder, you can get the most out of your grinder tips and machine productivity, while minimizing the frequency of changing tips.

Abrasion-resistant tips

Impact-resistant tips

Impact-resistant (I/R) tips offer an alternative to wing tips and are used to process large-diameter material. Their carbide inserts are very hard and are not recommended for use when contamination or rocks are present. I/R tips can be flipped for extended life.

Narrow block tips

Narrow block tips only in the standard configuration are available for tub grinders and select horizontal grinders. They have an overlay of carbide along the sides of the block, making them an effective solution for processing large-diameter woody material. Narrow block tips can be flipped for extended life.

Sharp tips

Sharp tips are precisely designed for cutting. They are most commonly used on large-diameter wood for maximized production and low amount of fines. With a sharp leading edge, these tips are not recommended for high contamination. Sharp tips can be flipped for extended life.

Wide block tips

Wide block tips are the most common in the industry. They can be used in a variety of applications such as land clearing, regrind, pallets, compost and green waste. Wide block tips can be flipped for extended life.

Wing tips

Wing tips have a unique design with an overlay of carbide that provides an effective solution for processing large-diameter woody material — a narrow center section helps the tip penetrate the log, then the wings clean out the remainder. Wing tips can be flipped for extended life.